A Client-trusted Partner of Global Timble Supply Chain

How much furniture can be made from one ton of rosewood?

At most, one ton of rosewood can be used to make 600 jin of furniture.

Where does the remaining 1,400 jin go? Zhou Lusheng, an expert on Ming and Qing furniture, once proposed his own calculation of the yield rate of rosewood: after drying, 15% of the weight is lost due to water evaporation; 8% is lost on average due to cross-cutting; 8% is lost due to planing; 18% is lost due to carving and shaping; and 20% is lost due to discarding the white sapwood from cracked and damaged parts. The actual utilization rate is 31%.

Therefore, please don't think that one ton of material can make one ton of furniture.

Here I will tell you today that during the production process, how redwood is wasted. The redwood's cutting process, including the cutting of large and small pieces, the adjustment of straight and curved materials, etc., will produce a large amount of wood powder and sawdust, and a considerable amount of redwood will be wasted.

According to the calculation of Ming and Qing furniture expert Zhou Lusheng, the loss is 8% of the entire log.

During the cutting process, parts containing white bark, wormholes, and rotten cores will be removed. This is the stage that generates the most complete waste materials. The waste materials of various redwoods are different, but the proportion of discarded wood can reach an average of 20%. These waste materials are completely unusable for making furniture.

Redwood timber needs to be dried multiple times before it can be used. After drying, the water loss is 15%, which means the weight of the redwood will decrease by 15%.

Generally, wood is dried three times before being made into furniture, and the boards and square timbers are dried separately.

The mortise and tenon technique in redwood: making mortise holes, cutting tenons, adjusting the wood, etc., inevitably generates a batch of sawdust and offcuts.

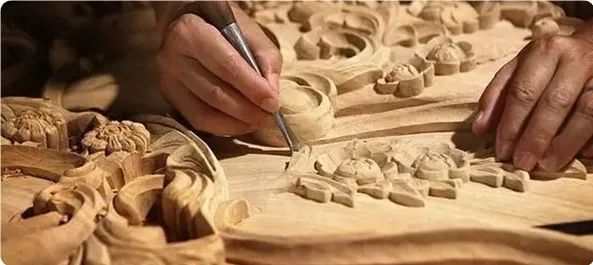

After carving and shaping, 18% of the wood is lost.

Before the furniture is coated with lacquer after assembly, it needs to be sanded and scraped with more than ten kinds of scraping tools to make it smooth. After the scraping is completed, it still needs to be sanded with sandpapers of different grits to make the texture of the furniture fine. During this process, a lot of wood is wasted.

After the lacquer is applied and the redwood furniture is completely finished, it still needs to be dried in the shade for 20 to 25 days before it can be sold to consumers. This will remove some moisture and reduce the weight. Therefore, the actual utilization rate of one ton of wood is only 31%, or even lower. ……

This article is excerpted from the WeChat official account: Wood Network News.

Keywords:

More Blogs

How to correctly distinguish genuine from fake Sapele wood?

A license to ensure smooth passage of timber? This African country has made it happen!